Simulation

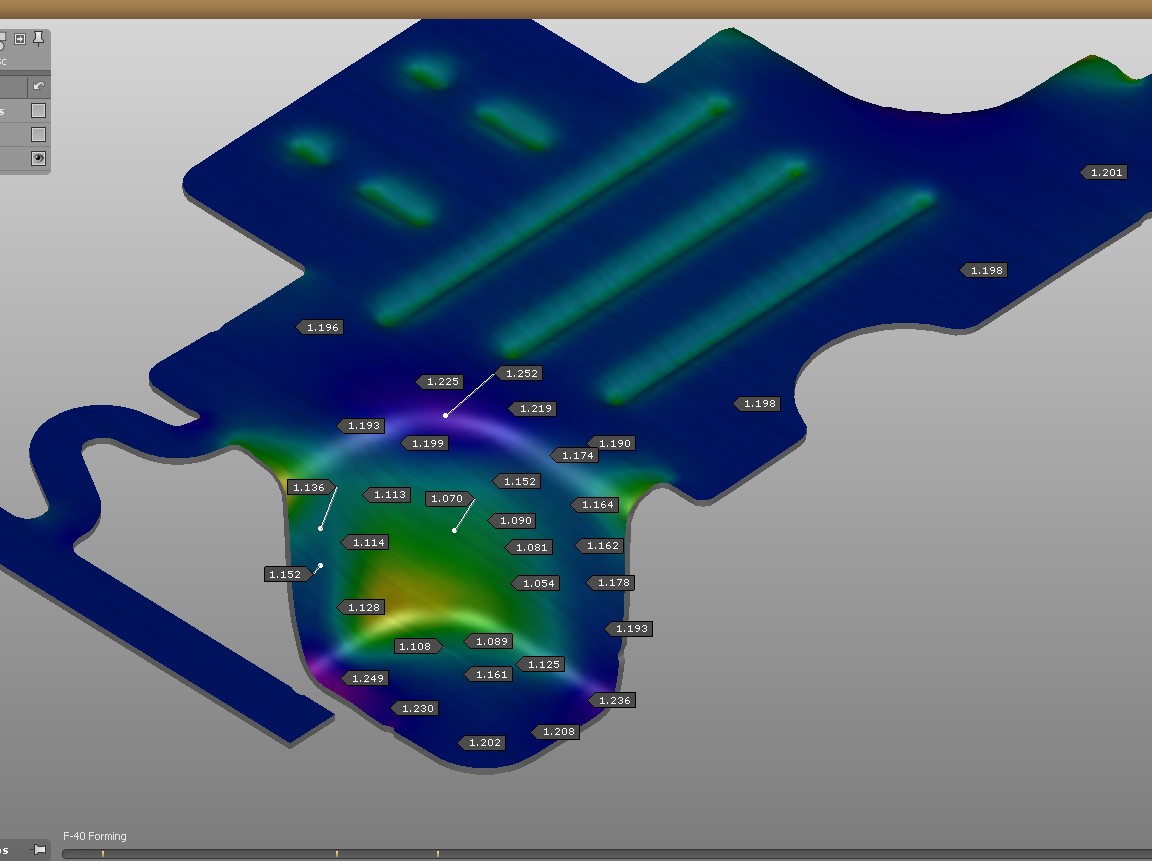

Our simulation department utilizes AutoForm software to validate and optimize die designs before manufacturing begins. By analyzing material flow, formability, and potential issues, we ensure that each die performs flawlessly in production. This advanced simulation process helps reduce trial-and-error, minimize waste, and improve efficiency—delivering cost-effective solutions that meet the highest quality standards.

Simulation Analysis & Testing evaluates:

-

Compression

-

Trim line optimization

-

Thinning

-

Wrinkling

-

Spring back and compensation

-

Splitting

Surface/Internal stress testing also measures:

-

Die wear

-

Radial and axial displacement

-

Effective, mean, radial, axial, hoop and shearingstress and strain

-

Radial and axial displacement

-

Volumetric strain

-

Load

-

Distortion due to forming load